- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

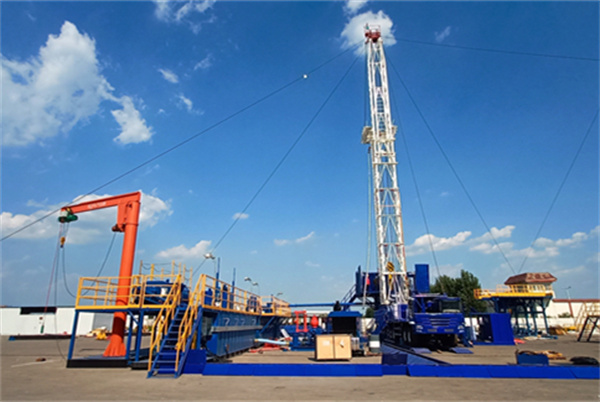

Equipment treatment effect of KOSUN geothermal well mud solids control treatment system

Aug 30, 2022

Geothermal well mud refers to the mud used for geothermal well drilling. The most prominent feature of geothermal well mud is high temperature resistance. High temperature will cause the mud clay to disperse, thicken, and even solidify due to high temperature, which will destroy the mud performance and cause the well wall to collapse, wellbore overrun, diameter reduction, drill bit mud bag, plugging closed production layers, etc. Therefore, the mud treatment of geothermal wells is a key problem in geothermal drilling. The geothermal well mud treatment process must be equipped with corresponding professional solid phase control equipment. The selection of geothermal well mud is mainly determined according to the specific temperature of the geothermal well.

Geothermal well mud has the following characteristics:

1) Control blowout: it is not suitable to use high-density mud.

2) Mud treatment agent: Due to the high temperature of the geothermal well, the mud treatment agent is guaranteed to be above 150°C to maintain stable mud performance.

3) Heavy metal preparations: It is strictly prohibited to use to prevent environmental pollution.

4) Fine solid phase particles: Ensure that the content of solid phase particles is the minimum value.

5) Mud treatment equipment: must be equipped with solid phase control equipment.

KOSUN can process the mud solid particles produced by different geothermal well temperatures. The equipment of the geothermal well mud solids control treatment system includes: mud shaker, cyclone desander, desilter, mud cleaner, Centrifuge, sand pump, shear pump, submerged slurry pump, mud mixer, jet mixing device, mud gun, grit chamber, purification tank, etc. Through the treatment of geothermal well mud solids control equipment, the solid content in the mud can be effectively controlled, and the solid particles in the mud can be controlled below 5 μm to 15 μm, and at the same time, the life of the mud pump and drilling rig can be prolonged, and the drilling speed can be increased.