- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

- Drilling Mud Cooling System

- Liquid Mud Plant (LMP )

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Drilling fluid decanting centrifuge operating principle in oilfield

Dec 12, 2023

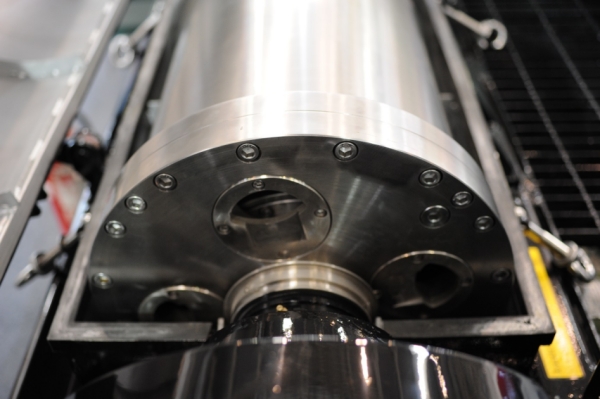

A drilling fluid decanting centrifuge (also known as a solid bowl centrifuge) separates continuously solid materials from liquids in the slurry and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries.

The drilling fluid decanting centrifuge separates the suspending fluids using the principle of centrifugal action, the suspending fluids are pushed into the rotor drum through the inlet pipe and the fluid hole of the spiral feeder. Under the influence of centrifugal force, solid phase particles are pushed to the internal wall of the drum, then to the mud export of the small end of the drum, and excreted. But the fluids are excreted from the overflow hole of the large end. Such a cycle is to achieve the purpose of continuous separation. A high-speed drilling fluid decanting centrifuge is effective for separation.

Drilling fluid centrifuge operating principle

The drilling fluid decanting centrifuge key part is a screw conveyor and transmission. When centrifuge work, drilling fluid will flow into the centrifuge through drilling fluid input. Then the roll bowl will increase speed and fluid will flow into the centrifuge through one fixed input pipe. Since the rolling bowl rotates at a rather high speed.

Drilling mud decanter centrifuges are designed specifically to remove unwanted solids and fine particles from virtually all kinds of used drilling mud, including those based on water/synthetics and conventional oil-based drilling fluids.

Tags: horizontal decanter centrifuge, drilling fluid decanting centrifuge, decanter centrifuge

Tags: horizontal decanter centrifuge, drilling fluid decanting centrifuge, decanter centrifuge