- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Introduction to the advantages of KOSUN's Mud Zero Discharge System

Jun 28, 2021

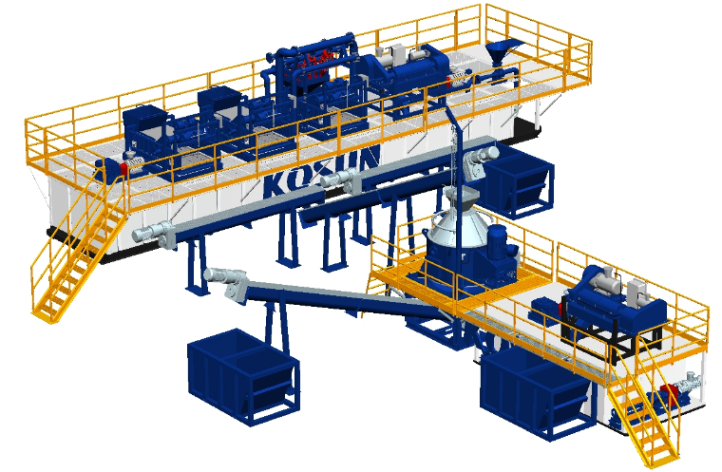

The Mud Zero Discharge System developed by KOSUN mainly includes shale shaker, centrifuges, cuttings dryers, and screw conveyors. After processing, it can reach an oil content about 2-5%, which is in line with national and industry standards.

After dewatering centrifuge separation and multifunctional purification unit, the harmful part of the mud is discharged with the solid phase. The liquid phase can be used to prepare the mud, discharge as wastewater or irrigate, and the solid part is solidified and then landfilled.

On-site centralized processing while drilling, using physical centrifugal separation technology to recover most of the base oil on-site, reducing the oil content and total amount of waste (the solid phase oil content of the spin dryer is 2%-12%, and the solid phase oil content of the centrifuge is about 13%, the treated solid phase is transported to the centralized treatment station for further treatment, and the liquid phase is returned to the circulation system for use. The advantage of on-site centrifugal deoiling while drilling is that it reduces the total amount of waste at the source, recovers reusable oil-based mud, and the treated waste is easy to store and transport, which greatly reduces the time and energy consumption of subsequent processing.