- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

KOSUN KD250 Separation Plant Can Be Used for Micro Tunneling Construction Projects

Aug 18, 2023

KD250 separation plant can separate larger solid particles from mud and reduce the solid content of mud. Mud treated by this system can enter the next-level treatment equipment such as centrifuge or filter press.

KD250 separation plant adopts modular structure design. This system mainly consists of shake shaker, cyclone, cone tank, feed module. Mud enters the screening system from feed module and is processed step by step by the coarse screen , cyclone, fine screen, excavation materials such as sand, stone and the like carried in the mud can be effectively separated, and larger solid particles in the tail slurry can be separated, thus reducing the solid content of the mud. Mud treated by this system can enter the next-level treatment equipment such as centrifuge or filter press.

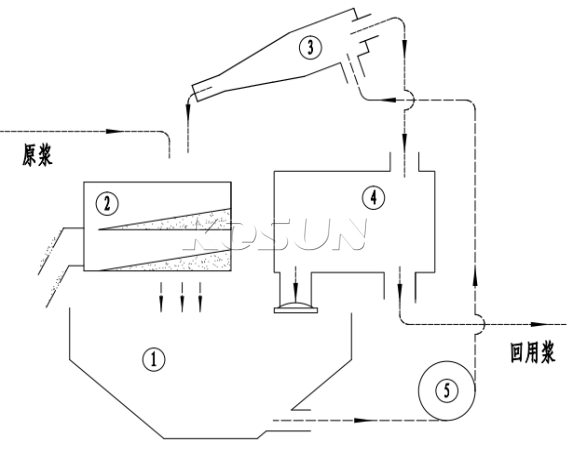

Step1: Raw slurry carrying silt is transported to the equipment through a slurry supply pipeline, enters the coarse screen(lower screen)of the double-layer vibrating shaker(2), and solid particles with larger particle sizes are discharged from the slurry treatment device.

Step 2: The mud treated by the coarse screen flows into the slurry storage tank (1), and then is pumped into the cyclone (3) by the slurry pump (5) to further remove the mud and sand from the original mud.

Step 3: The large-diameter sand in the original mud is discharged through the underflow port of the desanding cyclone (3), falls onto the fine screen (upper screen) of the double-layer vibrating shaker (2) for dehydration, and is then discharged out of the mud treatment device.

Step 3: The large-diameter sand in the original mud is discharged through the underflow port of the desanding cyclone (3), falls onto the fine screen (upper screen) of the double-layer vibrating shaker (2) for dehydration, and is then discharged out of the mud treatment device.

Step 5: The liquid level floating ball installed on the mud return tank (4) controls the liquid level of the slurry storage tank (1). Only when the liquid level of the slurry storage tank (1) reaches