- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- MD210 Drilling Mud Cleaner

- Balanced Elliptical Motion Shale Shaker

- Oilfield Drilling Mud Desander

-

Solids Control System

- Drilling Mud Cooling System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Sludge water treatment system site layout and equipment selection

Feb 14, 2025

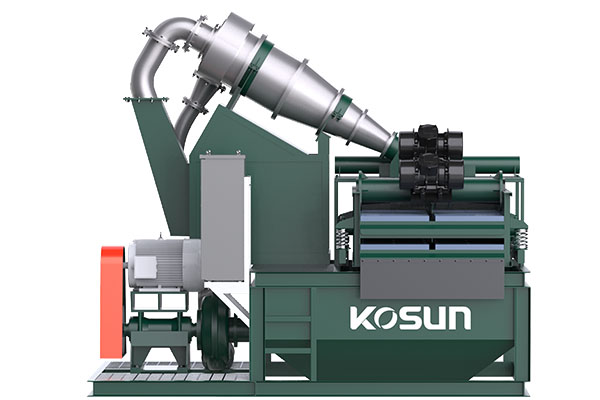

Slurry water treatment system is mainly set on the ground, by the pulping system, slurry system, slurry water transport system and slurry water separation system of 4 sub-systems, mainly including swelling tank, slurry mixing tank, water tank, return slurry tank, sedimentation tank, cyclone, vibrating screen, filter press and a variety of valves, pipes and pumps. The slurry prepared by the pulping system, after adjusting the index of the pulping system, is transported by the slurry conveying system to the slurry tank of the shield. The slurry sent to the surface by the slurry pump is separated and discharged step by step according to the particle size by the pre-screening treatment, the primary cyclone treatment and the secondary cyclone treatment. The slurry after the separation of the residue is sent to the slurry mixing system again for property adjustment, so that it becomes a high-quality slurry and then recycled to the slurry tank.

The maximum slurry capacity of the separation system is 3 300 m3 /h, with 3 stages of separation: The first stage is pre-screening separation, using the vibration of the vibrating screen to sift out the particles with a particle size of more than 3mm in the mud, the second stage is 1 stage swirl separation, the separation particle size d50 = 74μm, the third stage is 2 stage swirl separation, the separation particle size d50 = 20μm. Cyclone working principle: Under the action of pressure, the mud passes into the cyclone, and the slurry fluid inside the cyclone produces high-speed rotation. Due to the effect of centrifugal force, the larger particles are thrown to the inner wall and discharged from the underspillway along the conical shell under the action of self-weight. At the same time, negative pressure is generated at the center of the high-speed rotating cyclone. Fine particles with low specific gravity flow out of the upper spillway under the action of negative pressure.