- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

- Drilling Mud Cooling System

- Liquid Mud Plant (LMP )

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

The Classification and Working Principle of Shale Shaker

Dec 19, 2017

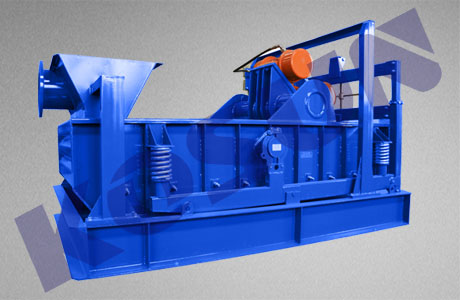

Shale Shaker is a vibration screening machinery used for treating refractory materials. The shale shaker has the process characteristics of large amplitude, high vibration intensity, lower frequency and flexible screen surface. During the work process, shale shaker always maintain the largest open-hole rate with high screening efficiency, processing capacity, easy to replace sieve, reducing costs. Shale shaker large screen surface and large processing capacity can meet the production needs of the scene.

The Classification of Shale Shaker

- According to use, shale shaker can be divided into mining shaker, light fine shaker, Vibrating shaker.

-Mine shaker can be divided into: high-efficiency heavy-duty shaker, self-center shaker, elliptical shaker, dehydration shaker, round vibrating shaker, banana shaker, linear vibrating shaker.

-Light fine shaker can be divided into: vibrating shaker, linear shaker, vertical shaker, ultrasonic vibrating shaker, filter shaker.

-According to the material running track, shale shaker can be divided into: linear vibrating shaker and circular vibrating shaker.

Working Principle of Shale Shaker

When the shale shaker is working, the two synchronous motor reverse rotation so that the exciter produce reverse excitation force, forcing the sieve mesh sieve to do longitudinal movement, so that the material on the subject by the exciting force and periodically throw forward a range to complete the material screening operations. Shale shaker is suitable for screening quarry stone, also for coal preparation, mineral processing, building materials, electricity and chemical industries for product classification.

Shale shaker working part is not moving, by sliding along the face of the material so that the material is screened. Fixed grid sieve is more commonly used in the concentrator, generally used for pre-screening coarse or broken before. It is simple in structure and easy to manufacture.

Shale shaker working face is composed of a horizontal scroll shaft, the plate has a shaft, the fine material from the gap between the roller or plate through. Large pieces of material driven by the roller to move one end and discharged from the end. Working part of the shaker cylindrical, the sieve around the cylinder axis rotation, the axis installed in general tilt. Material is fed from one end of the cylinder, fine-grained material passes through the mesh openings in the cylindrical work surface and coarse material is discharged from the other end of the cylinder.