- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

- Drilling Mud Cooling System

- Liquid Mud Plant (LMP )

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Common Equipment for Drilling waste management

Oct 14, 2016

Along with continuously enhanced environmental requirements, the requirements on cuttings treatment on drilling sites are more and more higher. The technology of mud zero discharge can not only solve the field environmental problems well, but also conduct a secondary recovery of waste generated by solids control system on sites, thus maximizing the reservation of useful mud. The centralized solidification of post-treated cuttings can reduce damages caused by the field operation to the surroundings.

Equipment of mud zero discharge mainly includes the following machines:

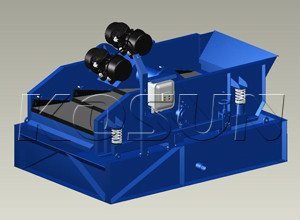

1. Hi-G Dryer

Features and Advantages:

1. Hi-G vibration intensity (adjustable as per working conditions).

2. Make drilling cuttings drier.

3. Bucket type feeder is more applicable to the field process.

4. Fast drilling cuttings conveying speed and higher handling capacity.

5. Screen frame tilt angle can be adjusted from -1° to 5°;

6. Rapid screen tensioning system ensures easy screen replacement;

2. Drilling Fluid Decanter Centrifuge

Features and Advantages:

1. Innovative design includes longer bowl, extending the retention time of drilling fluid in bowl, thus resulting in drier solids and finer cut point.

2. Anti-corrosion and wear-resistance bowl is available and the solids discharge ports are fitted with quick-replaceable hard alloy bushings (tiles).

3. Anti-corrosion and wear-resistance scroll is available and the scroll surface in contact with cuttings is welded with tungsten carbide layer.

4. German FAG or Swedish SKF brand bearings are available.

5. Electrical components comply with SIEMENS/Schneider ATEX or IEC Ex.

6. Screw pump and submersible slurry pump are available and can meet liquid feeding requirements of centrifuges of various customers.