- Home

- Products

-

-

Solids Control Equipment

- Linear Motion Shale Shaker

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Solids Control System

- Mobile Solids Control System

- Arctic Solids Control System

- Drilling Mud Cooling System

- Liquid Mud Plant (LMP )

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

Home > KOSUN News >

Oil-base Mud Zero Discharge Treatment

Jan 29, 2018

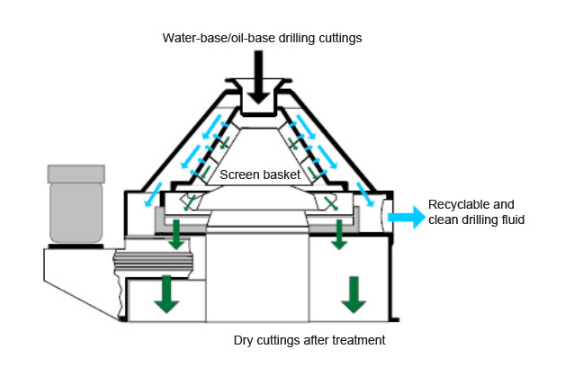

Oil-base Mud Zero Discharge Treatment Operating principles:

Oil-base mud cuttings enter the top hopper of vertical centrifuge and fall onto its internal separation area. The internal cone rotates at a high speed of 900RPM and generates a centrifugal force of 430G. For density difference between liquid and solids, mud is hurled out of surface of drilling cuttings and passes through screens, and solids are retained inside the screens. And then, liquid is discharged from the liquid outlet and dry solids are discharged from the bottom of equipment.

-Efficient solid-liquid separation. Liquid content of treated solids is up to national and industrial standards.

-Effective recovery of treated liquid for recycling in drilling solids control system.

-Greatly reduce solid discharge volume, drilling fluid cost and waste management cost.

-Meet field operation requirements on zero discharge of drilling waste.

-Rotate at a high speed of 900RPM to generate a centrifugal force of 430G and effectively separate liquid from cuttings.

-Flights coated with wear-resistant material and metal screens for longer service life.

-Intelligent pulse jet control system effectively prevents screen blockage.

-Separate oil circuit lubricating and cooling system for simple and reliable operation.

-Integrated programmable control system for safe and convenient operation.

-Feed/discharge ports can be equipped with screw conveyors to facilitate drilling cuttings conveying and continuous equipment operation.

Treatment Effects of Vertical Centrifuge:

For oil-base and synthetic-base mud: water content of solids treated by the vertical centrifuge is below 6%.

For water-base mud: water content of solids treated by the vertical centrifuge is within 5%~8%.