- Home

- Products

-

-

Solids Control Equipment

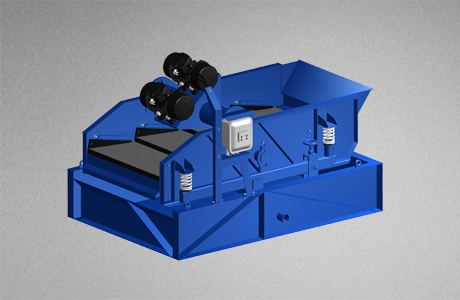

- Linear Motion Shale Shaker

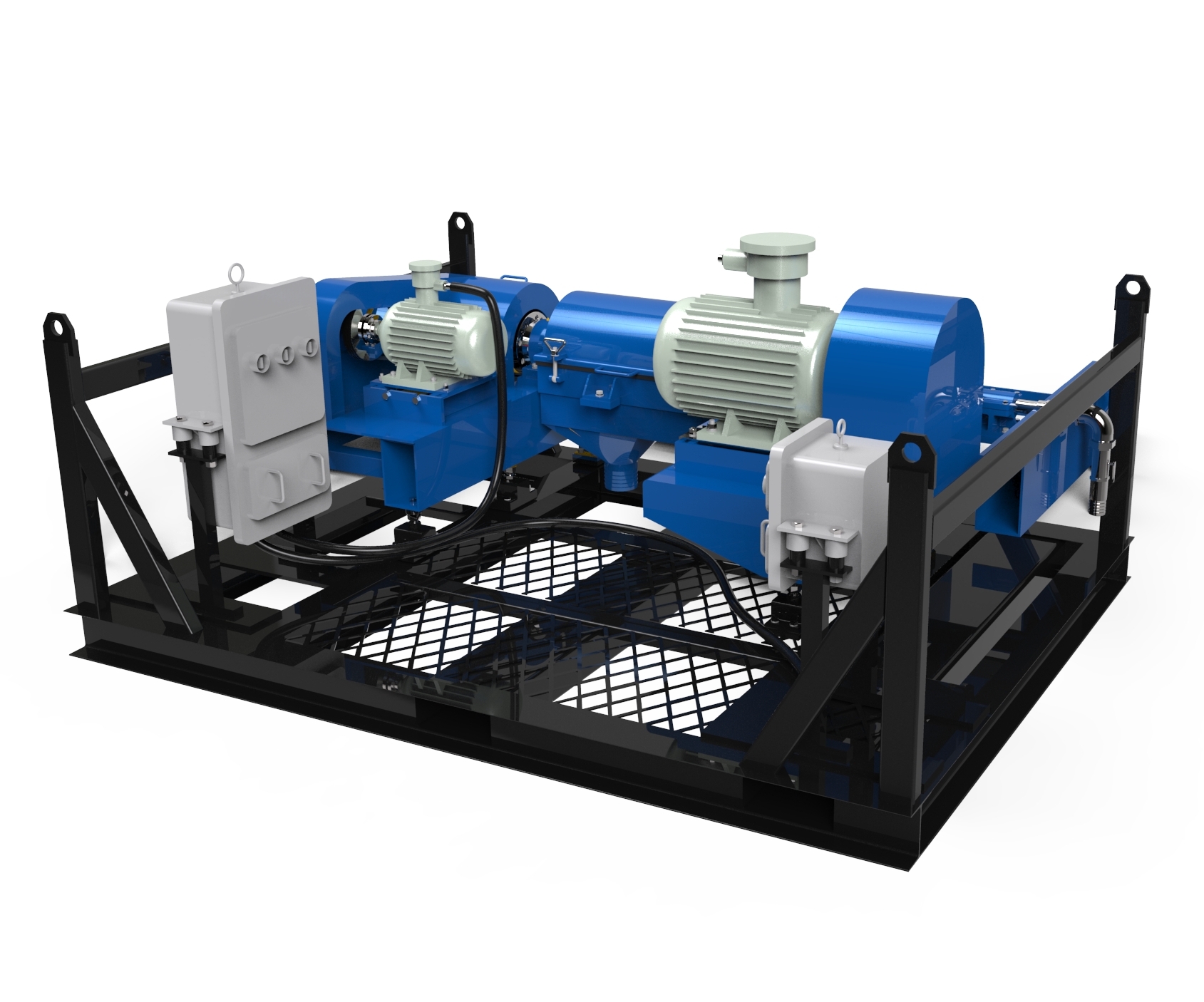

- Decanter Centrifuge

- Mud Cleaner

- Vacuum Degasser

- Centrifugal Pump

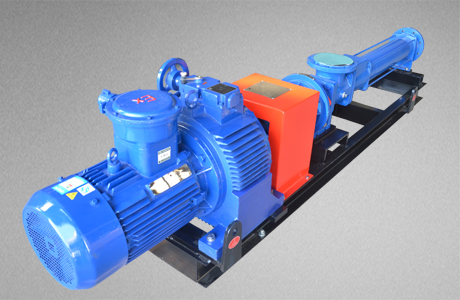

- Shear Pump

- Submersible Slurry Pump

- Mud Agitator

- Mud Gun

- Jet Mud Mixer

- Desilter

- Water Tank

- LS606 Shale Shaker

- Mud Tank

- LS1850 Shale Shaker

- Diesel Tank

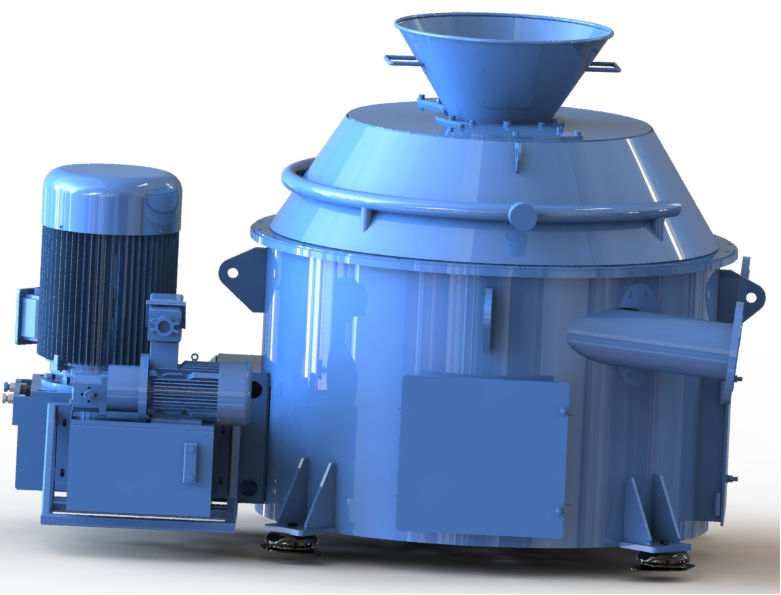

- Dome-shaped mud cleaner

- Vertical cyclone desilter

- KQG30 Automatic Tank Cleaning

- MD210 Drilling Mud Cleaner

-

Solids Control System

- Arctic Solids Control System

- Mobile Solids Control System

- Liquid Mud Plant (LMP )

- Solids Control System

- Drilling Mud Cooling System

-

TBM

- Tunnel Boring Mud System

-

HDD

- HDD Mud Recovery System

-

-

- News

- Services

- Marketing

- About Us

- Contact Us

- Videos

1m³/h Oily Sludge Treatment System

1m³/h Oily Sludge Treatment System, efficient separation of a three phase oil, water and solid, to achieve resource recovery and standard disposal

send an E-mail us

send an E-mail us- We're here to help:

- Easy ways to get the answers you need.

+86 13379250593

+86 13379250593 office@adkosun.com

office@adkosun.com

Features

System Introduction of 1m³/h Oily Sludge Treatment SystemThe 1m³ oily sludge treatment system independently produced by KOSUN Machinery is an efficient solution specifically designed for the harmless and resourceful treatment of various types of oily sludge.The core of the system adopts advanced chemical hot washing technology, which can maximize the recovery of crude oil from the complex sludge mixture, and realize the recycling of water resources and the standard treatment of solid phase residue. With its significant investment cost advantage and excellent treatment efficiency, the system has become an ideal choice for the treatment of oil waste in petroleum petrochemical, oilfield exploitation, oil storage and transportation, etc.

Application Scope of 1m³/h Oily Sludge Treatment System

Landing sludge from oil field operations, equipment leakage, etc.Waste oil-based mud and drill cuttings produced during the drilling process.

The oil residue and sludge produced during the cleaning of oil storage tanks and transport tanks.

Sediment deposited in oily wastewater sedimentation tank and catchment pit.

Processing Effect of 1m³/h Oily Sludge Treatment System

After being processed by this system, all phase products can reach the industry-leading standards, achieving efficient separation and purification of the "oil, water and solid" three phases.

The oil content of the solid-phase residue is less than 2%, which is far lower than the national general hazardous waste landfill standard. This creates favorable conditions for subsequent advanced disposal (such as pyrolysis, incineration, and biodegradation), significantly reducing disposal costs.

The oil content in the liquid-phase effluent is as low as 200mg/L, and the water quality is clear. It can be reused in the system's own cleaning or hot washing process, achieving the internal circulation of water resources within the factory and saving the consumption of fresh water and the cost of wastewater discharge.

Core Process of 1m³/h Oily Sludge Treatment System

1. Chemical hot washing process

By adding a specially formulated surfactant and cleaning agent, at an appropriate heating temperature, the stable "water-oil-solid" emulsified structure in the oil sludge is disrupted, effectively reducing the adhesion force between the oil phase and the solid phase particles, allowing the crude oil to be fully stripped and released.

2. Multi-stage centrifugal separation process

The mixture after hot washing enters high-efficiency multi-stage centrifugal units (such as decanter centrifuge, disc centrifuges, etc.). By precisely controlling the centrifugal force field, the fine separation of oil, water and solid is achieved:

(1) Light phase: The recovered crude oil has a relatively high purity and can be directly sold to refineries as raw materials, generating considerable economic benefits.

(2) Middle phase: the separated water phase can be reused after simple treatment in the system to form a closed loop.(3) Heavy phase: Solid residues with extremely low oil content, meeting environmental protection requirements.

System advantages of 1m³/h Oily Sludge Treatment System

1. Maximizing resource recovery: High crude oil recovery rate, turning waste into treasure, directly generating economic benefits.

2. The treatment effect is stable and reliable, ensuring that the solid residue and effluent quality consistently meet or even exceed the design standards.

3. The process is mature, with controllable energy consumption and chemical costs. The recycling of water bodies significantly reduces water consumption and sewage discharge fees.

4. Compared with incineration, pyrolysis and other high temperature and high pressure processes, high return on investment, combined with oil sales income, short investment payback period.

5. The entire process realizes reduction, harmlessness and resource utilization, helping enterprises achieve environmental protection goals.

Destination of the final product

1. The recovered oil products, such as good quality, can be sold as raw materials for refineries to realize resource reuse.

2. The purified water is recycled within the system, which saves energy and reduces consumption.

3. If the oil content of the deoiling solid phase is less than 2%, it can be sent to a professional institution for pyrolysis (further recovery of energy and solid phase resources), incineration (complete harmless treatment), or biodegradation (ecological restoration) in accordance with local environmental protection policies, ultimately achieving harmless disposal.

Services

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Vertical Cuttings Dryer

Vertical Cuttings Dryer Hi-G Dryer,Drying Shaker

Hi-G Dryer,Drying Shaker Screw Pump

Screw Pump 1m³/h Oily Sludge Treatment System

1m³/h Oily Sludge Treatment System VC700 Vertical Cuttings Dryer

VC700 Vertical Cuttings Dryer The KFCQ300 vertical degasser

The KFCQ300 vertical degasser  D Series Decanter Centrifuge

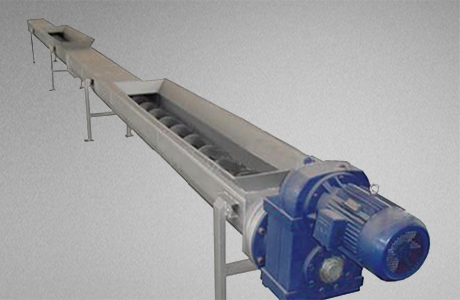

D Series Decanter Centrifuge Screw Conveyor

Screw Conveyor